|

How

to rebuild a crankshaft

|

|

|

|

|

Right,

now you’ve made the stand this what you do with it.

To

split the crankshaft, firstly put the stand in the vice with the two bits

pointing upwards.

Place

the crank with the timing side shaft facing upwards, on to the stand, there

is no need to use the clamp that you made just yet! Firstly, undo the screws

and remove the locking plates these can be a bit stubborn to get off, but

you can insert a screwdriver under them and gently praise them off, taking

care not to bend them as you will re-use them. Using a long ratchet or

breaker bar undo the nut, the reason that you put it in the stand this way

up first is because BSA cranks are keyed on the primary side of the crank.

With the nut undone get a copper/ hide mallet and strike the timing side

flywheel on the side, try to use one sharp tap rather than lots of little

ones, the flywheel should then break off its taper and can be removed.

|

|

|

|

When

you have removed this flywheel, you can take off the connecting rod and the

bearing cage and rollers, now you can remove the crankpin, by turning the

crank over in the stand and undoing the nut on the remaining flywheel, then

simply give the crank pin a sharp tap with the mallet on its threaded end.

|

|

|

|

Now

the crank is split, you should clean up all the components, personally I

bead blast them and then use a “Scotch” pad or wire wool, the reason I

use a two step process is because if you just bead blast them they tend to

rust rapidly, if they are given a bit of a polish is this tends to make them

a bit more rust resistant, besides the fact it looks pretty!!!

This

picture below shows the standard that you should try to achieve

|

|

|

|

The

reason that you give everything such a good clean is that the longer you

handle the components, the longer you have to notice any defects, if you

just give them a quick clean you may miss a slight crack in the flywheel or

the loose rivet on the shaft.

Now

the components are clean, you can now decide on the best course of action to

rebuild it, you can ignore all of this if you have a new crankpin and rod

set! As we are trying to save you money we’ll do this the cheapest way!

Firstly

decide where most of the wear is, if you have a micrometer you can check the

wear on the rollers, but you usually find that they are worn 0.002 inch or

0.003 inch and the rod race in the connecting rod has a tiny bit of wear

along with a couple of pits in the crankpin (this is what I usually find!)

if there is a lot of pitting or deep witness marks where the rollers have

sat stationary on the crankpin for a long time and the acids in the oil from

combustion have etched the surface of the crank pin,

you may as well throw it away and get another one!

What you have to decide is where most of the wear is and concentrate

on trying to remove the wear or damage on that particular component and just

basically refresh the surface on the other component.

To

clean up the crankpin, the best way is to put it in the lathe and with emery

tape and polish the surface this can also be achieved by clamping the two

ends of the crankpin in the vice and using the emery tape in a backwards and

forwards motion, making sure in this instance that the tape does a full loop

of the pin so that it cleans it up evenly this will actually take quite a

while so don’t be scared of taking off too much, obviously doing it in a

lathe is a lot quicker this should be done irrespective of the pin looking

in good condition as you will be using a long one piece roller and

there will be a microscopic ridge where the ends of the two separate were

running alongside each other. See photo below

|

|

|

|

To

clean up the connecting rod race, it is a bit more difficult for the amateur

to achieve. I personally use a honing machine but I’ve got a big

workshop!! You can use a spring type hone running at a slow speed but this

does not remove any slight ovality in the race a better method is to use a

Delapena hone or better still take it to an engine reconditioners and get

them to do it. Basically you

are trying to get a good fit with the new rollers and restore the running

clearance on the big end, usually you will find that the 0.001 inch oversize

rollers won’t fit in there straight away, and you have to make the

decision to remove a bit more metal on the most worn/ damaged surface. In

some instances it may pay you to take the whole lot to an engine

reconditioners and explain to him the contents of this section and let him

sort it out for you. The cost shouldn’t be much, I have all the machinery

and it only takes about a quarter of an hour to sort it out. The photo below

is of the connecting rod being cleaned up on a horizontal honing machine.

With

regard to the tapers in the flywheels, check them for ridges near the

outside edge where the crankpin has pushed up a sliver of metal when it was

initially tightened, if one is visible you should try to remove it by gentle

filing, taking care not to damage any other part of the taper, the tapers

sometimes wear when the engine is used as a brake, one flywheel will try to

ride over the other and this movement over a period of time will cause the

taper to wear. You can also check the amount that the flywheel grips the

crankpin, by looking for a wavy line in the taper, another way is to put

some engineers blue on the taper and turn it a few times and see that it has

been removed evenly. There is no real way on a BSA to machine the tapers as

this would be too close to the shoulder on the crankpin and you couldn’t

be sure that it wasn’t only gripping just on the shoulder, Old M20 cranks

are cheap so it would probably pay you to obtain another set in this

instance. Don’t even think about using grinding paste unless you want to

make matters worse!

|

|

|

|

A

nice finish on the connecting rod race should be a nice crosshatched finish

at about 120 degrees.

Now

would be a good time to put a new small end bearing in, you can do this by

using a socket that is slightly smaller that the outside diameter of the

bushing but still has a large enough diameter to not jam in the bush as you

press it and on the other side another socket whose inside diameter is

larger than the outside diameter of the bush but not too big as you want it

to sit on the “eye” of the connecting rod. Simply sandwich the rod

between the two sockets and tighten the vice, the bushing should be slowly

pressed out into the larger socket Hey Presto and its out! To put the new

one in simply squeeze it in using the vice, don’t forget to drill the oil

hole in it then, just ream it out.

Now

you are ready to reassemble the crankshaft!

Firstly

place the woodruff key in the crankpin and ensure that there are no traces

of oil or grease on the tapers of either the crankpin or its mating part on

the flywheel, if there is the pin will not seat properly in the taper, it

would be as if it is floating on the oil and will never stay tight where you

put it so it should be cleaned with thinners or acetone, needless to say

that you have blown out the crankpin and the oil way in the mating flywheel

before you start this and made sure that everything is scrupulously clean!!

Place

the crankpin in the flywheel and tighten up to 100 ft lbs, I find that if

you do it in stages it moves when you do the final tightening, when it is

torqued up try on the lock washer and see if it lines up, if it doesn’t

you can tighten it up a little bit more until it does, but before you do try

both lock washers on both ways round, it may fit as the lock washers are

sometimes slightly different. If the lock washer doesn’t line up, never

slacken it to get it to line up!

|

|

|

|

Now

after putting the bearings in and the rod on, you can place the other

flywheel on top and just nip the nut to about 20 ft lbs, then place the

truing clamp as close to 90 degrees away from the crankpin as you can, this

needs tightening up pretty tight to get the flywheels in line then you must

slacken it off and have it at about 15 ft lbs this initially trues the

flywheels then lets them pull together evenly (so that the flywheels don’t

just pull together by the crankpin and leave the side opposite so tightly

clamped that they don’t pull in evenly) Now all you have to do is tighten

it up to 100ft lbs and once again check that the locking washer lines up.

This is your crankshaft now assembled.

Now

the fun bit!!! (Not)

It’s

time to true the flywheels, this is quite hard to explain and you’ll find

that the more you do the easier it becomes, but it does help to do it in a

set order. The first thing you’ll need is a lathe or a crank truing stand.

If you have a lathe you will need two centres, you could machine up another

one from round bar, one in the tailstock and leave the one you’ve just

machined in the chuck!

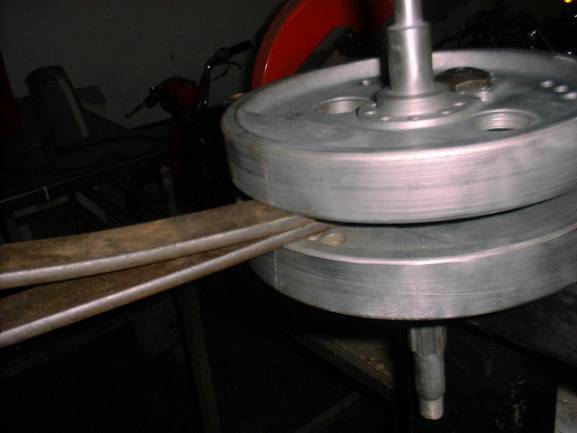

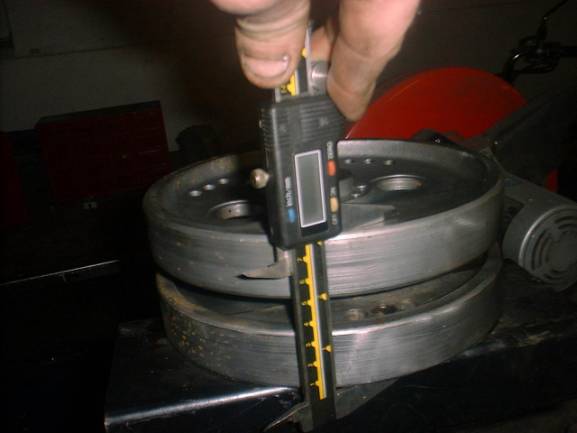

First

things first you must make sure that the flywheels do not run out across

their outside edges, it is best to do this on the stand when you’ve

tightened up the nuts, you will find a digital vernier caliper best for

this, all you have to do is take a measurement across the flywheels by the

crankpin, and another one directly opposite, then another at 90 degrees to

the last and then another directly opposite this one, this will tell you

where the run out is, if one side is too high you can squeeze it in the vice

or with a G clamp, the main reference point for all these measurements is

the crankpin as all sides of the flywheel should be in line with it. If the

opposite side to the crankpin is too small a measurement you can open up the

gap between the two flywheels with a pair of tyre levers levering them

apart. See the photos below to see what I mean.

|

|

|

|

The

picture below shows where the measurement should be taken, then at 90-degree

intervals around the rim, if the measurement is larger than on the crank pin

side, you must squeeze the flywheels together, and if the measurement is

smaller you must spread the flywheels with the tyre levers.

|

|

|

|

When

you have got the measurement to within about 0.002 inch or less, you can now

put the crank into the lathe or truing stand to do the final truing. You

should place the crank in the stand and adjust the tailstock so that the

crank has no lateral play, in other words there should be no free play so

the crank could move side wards and give a false reading and at the same

time not so tight that it is squeezing the flywheels together. Now it is in

the stand correctly positioned the following picture shows the crank in the

stand.

|

|

|

|

Place

your dial gauge on one of the shafts, this is the shaft that you now use to

index the run out from, you can use two gauges if you’ve got them as it

helps you understand why you have run out where you have it, but you can

still do it just as well with one. My own gauge is of the Verdict type but

you can also use the Mercer type, if you can get one that is calibrated in

0.0001 this is better as it allows you to see the run out sooner and as a

sweeping movement as opposed to a sudden “blip” from the needle.

Now

you must understand the types of runout.

|

|

|

|

By

understanding where the misalignment is you can correct it by carefully

hitting the flywheel rim in the appropriate place, as to how hard you have

to hit it is a matter of experimentation, it is better to hit it not hard

enough than to hit it too hard and throw the whole assembly out too far in

the other direction. It is better to start off giving it a “sharp tap”

than to hit it with a “crack”. Sometimes with this jig you can get it to

within a couple of thousandths of an inch first time, and other times it may

take half an hour to get it spot on, it will always true up easier if you do

it in the logical way, by sorting out the run out on the flywheel edge, then

tackling the other types of run out.

The

hardest type to get trued up is where one flywheel is higher than the other

one, and by experience usually, the only way to sort this out is to split

the flywheels and try again after using a little emery paper on the tapers

hoping that it will allow the taper to reseat itself in the correct place,

the picture shown below shows an exaggerated view of the taper problem.

|

|

|

|

By

removing the burr you should hopefully allow the taper to reseat itself.

|

|

This

just about covers most of the problems encounters whilst crankshaft

rebuilding. If you find that you can’t get the crank to run truer than

0.005 inch the problem could be that the flywheel is defective, and you may

have to get new wheels. Usually you can true the crank to under 0.001 inch,

but on an M20 you could happily run it with about 0.003 inch (the bearings

will usually allow for this, but obviously the closer that you can get

absolute zero the better, as the engine will be smoother.

Good

luck! If you have any problems regarding crankshaft rebuilding please do not

hesitate to ring me on +44151 200 9161 (evenings)

Thanks

to Jake Plumb (for doing the drawings!)

©

Dave Plumb 2007

|