|

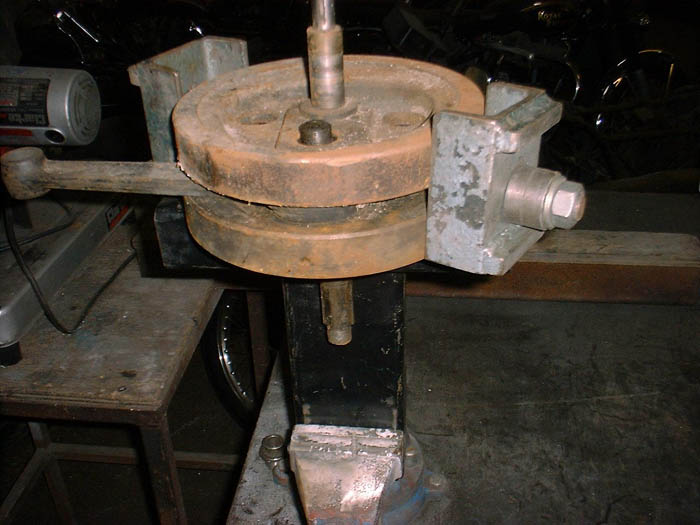

Crankshaft dismantling stand |

|

|

|

||

|

Here we have a

simple stand that you can use for dismantling and rebuilding the crankshaft,

not only on M20's but also most of the BSA pre unit singles. I made

this particular one out of box section, but you could just as well make it

from channel or angle iron, (about 3 inch minimum). I have found

that when making these stands that using exact measurements are no good, as

when you weld them up they pull slightly, so the best way is to make it

around the crankshaft that you have, that way, you are sure that it fits

perfectly. I make these stands from anything I have lying around, and

usually you can use the same principle on many other bikes that have

split crankshafts. This particular one cost me £3 for the steel (new) and

took me about 10 minutes to knock up the only thing that helps is a

welder, but you could equally drill and bolt one together. The first thing

to do is grind into the box in the centre to clear the main shafts,

then weld (or bolt) the bit that goes into the vice, then all you have to do

is weld/bolt on the tube or round bar that fits through the holes in the

flywheel, I found that welding these are on is the best way to do it

as you can tack weld the tube (which incidentally is a bit of old

handlebar) whilst the crank is sat on the assembly that way you

are sure that it is all going to fit together properly. Now you have made

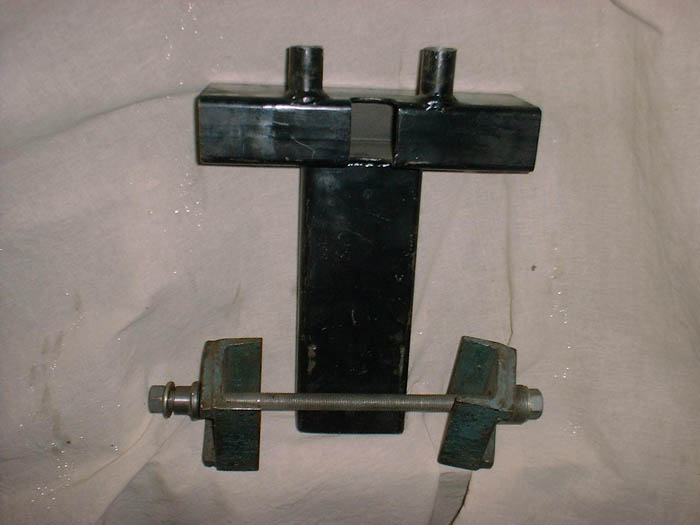

the stand! To make the truing clamp you do really need to make this from

channel section, this part allows you to hold the crank true to

within a few thousandths of an inch prior to final truing the threaded bar

that I've used in this particular one is 16mm diameter stock studding. When

you've made the stand, don't think that you can instantly true the

crank , it takes a little experience, in a couple of weeks I'm rebuilding an

M21 crank and I'll do a step by step "how to do it".

I hope you all find this useful, if you need any more information on making one or any aspect of crank truing please email me at davmax@ntlworld.com |

||

|

|

||

|

||

|

||